HiPer-tex®

With HiPer-tex® the high performance fibre, 3B delivers a step change in performance for users of glass-reinforced composite materials:

- high strength

- high modulus

- high elongation at break.

Competitive high performance

HiPer-tex® high performance fibre is the result of a groundbreaking development in manufacturing technology that enables high performance fibreglass to be produced at an attractive cost:

- new glass formulation

- specific melting, fiberizing and sizing technologies

- high capacity production platform for scale economy.

Compared with traditional E-glass, HiPer-tex® high performance fibre typically provides:

- + 25% in strength

- + 45% in strain energy

- 10 x in fatigue resistance.

Green technology

3B operates state-of-the-art manufacturing facilities. HiPer-tex® glass is produced in our eco-friendly glass fibre manufacturing facility in Birkeland (Norway), with a top priority to respect the surrounding environment.

Thanks to an advanced melting technology and a patented formulation that does not rely on adding boron or fluorides, the production of HiPer-tex® occurs at low manufacturing emissions levels.

Performance properties

A composite part leads an extremely challenging life. This calls for the development of new composite materials with exceptional and extremely durable properties. HiPer-tex® fibre is one of 3B’s solutions that address these challenges.

| Resin | Product | TP/TS | Features | Process | Length/Diameter ratio | Ø | |

|---|---|---|---|---|---|---|---|

| Epoxy specific | W 2020 | Thermosets | Higher modulus | Weaving, Non-crimp fabrics, Prepregs, Filament winding, Pultrusion | |||

| Polyester, Vinylester, Epoxy | W 3030 | Thermosets | Higher modulus | Weaving, Non-crimp fabrics, Prepregs, Filament winding, Pultrusion |

HiPer-tex® fibre properties

| Property | Test Method | Unit | HiPer-tex® fibre | E-CR Glass |

|---|---|---|---|---|

| Chemical Composition | No added Boron /No added Fluorides | – | ||

| Softening point | DIN ISO 7884-1 | °C | 925 | 886-904 |

| Density | g/cc | 258 | 2.54-2.62 | |

| CLTE (0°C to 300°C) | ASTM D696 | 10-6 K-1 | 4.1 | 5.4-6 |

Impregnated HiPer-tex® fibre properties

| Property | Test Method | Unit | HiPer-tex® fibre | E-CR glass |

|---|---|---|---|---|

| Tensile Strength* | ASTM D2343-08 | MPa | 2700-3200 | 2000-2600 |

| Tensile Modulus* | ASTM D2343-08 | GPa | 86-89 | 74-83 |

* Representative values of 17μm 2400 tex Advantex® Glass fibre, epoxy resin impregnated and depending on grades

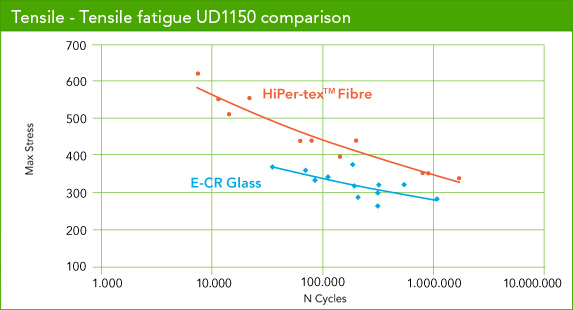

Fatigue mechanical properties

- Comparison of traditional E-CR reinforcement glass and HiPer-tex® fibre

- Epoxy unidirectional fabrics (UD 1150g/m²) laminates

- Tension/tension ratio: 0,1

* Representative values of 17µm 2400 tex glass fibre, epoxy resin impregnated and depending on grades

Courtesy of CRM Liège

Acid corrosion resistance

- Mimicked A14 Acid Environment test of United Nations R110 regulation

- Measurement of residual flexural properties of 100 hour immersed laminates in 30% H2SO4 solution @ RT. 35% strain level.

- HiPer-tex® fibre is suitable for applications in corrosive environment.

| Strength | Modulus | |||||

|---|---|---|---|---|---|---|

| Initial (MPa) | Final (MPa) | Residual (%) | Initial (GPa) | Final (GPa) | Residual (%) | |

| E-Glass 77,6% Wf | 1497 | 0 | 0 | 50.6 | 0 | 0 |

| HiPer-tex® Fibre 79% Wf | 1791 | 1659 | 92 | 56.5 | 56.4 | 99 |

Resistance to impact

- V50 comparison of polyester laminates reinforced with E-Glass, S2-Glass® and HiPer-tex® fibre.

- 5.56 mm FSP

- Tested at Banc Officiel d’Epreuve of St Etienne (France)

- S2-Glass® is a register trademark of AGY

| S2-Glass® | HiPer-tex™ fibre | E-glass | |

|---|---|---|---|

| Areal density (kg/m²) | 20.0 | 20.9 | 20.1 |

| V50 (2.5mm) (m/sec) | 900 | 828 | 655 |

HiPer-tex® high performance fibre

HiPer-tex® is 3B's high performance fibre: high strength, high modulus and high elongation at break.